One of the key pieces of a restomod that makes it exciting is a modern, reliable and performance-based motor. With a plethora of options out there we were curious to learn what exactly it is about LS engines that make them so popular.

So, why are Chevrolet LS engines so popular for restomods? LS engines are cost-effective, generate a lot of power, and are small relative to other motors so they are easy to swap and easy to find.

To answer this question more fully, we will outline the history of the LS engine, Chevrolet’s technology prowess which drove innovation, how the aftermarket contributes, and ultimately provide 6 reasons LS engines are so popular.

LS Engines – History In The Making

General Motors has been building small-block V8s since 1997. They initially called the engine the Gen III Small Block, and they had a signature iron-block version in trucks. The all-aluminum LS1 was introduced in the new C5 corvette. In 1999, the more powerful LS6 was released.

2004 saw the release of Gen IV performance versions with active fuel management (AFM) and variable valve timing (VVT). The performance versions of the Gen IV include the LS2, LS3, LS9 supercharged, LSA supercharged, and the LS7. LSx is a generic term for every platform engine.

There is a fairly wide range of LS engines in production. With regard to trucks, the iron-block engines have 4.8L and 5.3L versions as well as aluminum 6.0L and 6.2L premium engines. With regard to cars, engines include the 5.3L, 5.7L, 6.0L, 6.2L, and 7.0L displacements, with some even built for front-wheel drive.

A Closer Look – LS Engines In Detail

LS Engine Horsepower Comparison

| Engine | Horsepower (HP) |

| LS1 | 345HP @5600 RPM |

| LS6 | 405HP @6000 RPM |

| LS2 | 400HP @6000 RPM |

| LS3 | 430HP @5900 RPM |

| LS4 | 303HP @5800 RPM |

| LS7 | 505HP @6200 RPM |

| LS9 (supercharged) | 638HP @6500 RPM |

| LSA (supercharged) | 580HP @6300 RPM |

LS1/LS6

LS1 5.7L (346-cu-in) engines were produced between 1997 and 2004 in the US (Corvette, Camaro, Firebird, and GTO). In 2005, in other markets (primarily Australia). The LS6 debuted in the 2001 Corvette Z06 and was used until 2005 in the Cadillac CTS-V.

The LS1 and LS6 share a 5.7L displacement, but the LS6 production engine uses a unique block casting with enhanced strength, greater bay-to-bay breathing capability, and other minor differences. The heads, intake manifolds, and camshaft also are unique LS6 parts.

LS2

In 2005, the LS2 6.0L (364 cu in) engine and the Gen IV design changes debuted. It’s available in GM’s Corvette, GTO, and SSR roadster. It is the standard engine in the Pontiac G8 GT. Its larger displacement brought greater power. The LS2 is one of the most adaptable engines, as LS1, LS6, LS3, and L92 cylinder heads work well on it.

Luckily GM was actually really good at developing cylinder heads when they designed the LS engine. Throughout the years Chevrolet continued to perfect the LS heads. The LS2 heads were a slight step up from the LS1 heads.

LS3

Introduced on the 2008 Corvette, the LS3 brought LS base performance to an unprecedented level: 430 horsepower from 6.2L (376 cu in) – making it the most powerful base Corvette engine in history. The LS3 block not only has larger bores than the LS2, but a strengthened casting to support more powerful 6.2L engines, including the LS9 supercharged engine of the Corvette ZR1.

The LS3’s standard in the 2010 Camaro SS and Pontiac G8 GXP. The L99 version’s equipped with GM’s fuel-saving Active Fuel Management cylinder deactivation system. And, it’s standard on 2010 Camaro SS models equipped with an automatic transmission.

LS4

The front-wheel-drive Chevrolet Impala SS and Pontiac Grand Prix GXP use the 5.3L LS4 engine. The LS4 has an aluminum block and unique, low-profile front-end accessory system, including a “flattened” water pump, to accommodate the transverse mounting position within the Impala and Grand Prix. The engine’s rated at 303 horsepower and 323 lb-ft of torque.

The transverse-mounted LS4 was only used in FWD cars from 2005-2009.

LS7

A legend in its own time. The LS7 is the standard engine in the Corvette Z06 and its 7.0L displacement (427 cubic inches) makes it the largest LS engine offered in a production car. Unlike LS1/LS6, LS2, and LS3 engines, the LS7 uses a Siamese-bore cylinder block design – required for its big, 4.125-inch bores.

Competition-proven heads and lightweight components, such as titanium rods and intake valves, make the LS7 a street-tuned racing engine, with 505 horsepower. Most LS7 engines are built by hand, at the GM Performance Build Center in Wixom, Mich.

LS9

The most powerful production engine ever from GM, the LS9 is the 6.2L supercharged and charge-cooled engine of the Corvette ZR1. It’s rated at 638 horsepower. The LS9 uses the strengthened 6.2L block with stronger, roto-cast cylinder heads and a sixth-generation 2.3L Roots-type supercharger.

Like the LS7, it uses a dry-sump oiling system. It is the ultimate production LS engine. It’s built by hand at the GM Performance Build Center in Wixom, Mich.

LSA

A detuned version of the LS9, this supercharged 6.2L engine is standard in the 2009 Cadillac CTS-V. It’s built with several differences, when compared to the LS9, including hypereutectic pistons vs. the LS9’s forged pistons; and a smaller, 1.9L supercharger.

The LSA also has a different charge-cooler design on top of the supercharger. Horsepower’s rated at 556 in the super-quick Caddy.

LSX Commonalities

There are certainly some differences amongst LSX engines (or as GM calls it, Gen III and Gen IV cylinder blocks), but they all have the following things in common:

- 4.40-inch bore centers (like the original small-block)

- Six-bolt, cross-bolted main bearing caps

- Center main thrust bearing

- 9.24-inch deck height

- Four-bolt-per-cylinder head bolt pattern

- 0.842-inch lifter bores

- Distributorless, coil-near-plug ignition system

The most distinguishing differences between Gen III and Gen IV cylinder blocks are larger bores (on some engines), different camshaft position sensor locations – indicated by a move to the front timing cover area on Gen IV blocks vs the top-rear position on Gen III blocks – and, on most Gen IV blocks, cast-in provisions for GM’s Active Fuel Management cylinder deactivation system in the lifter valley.

GM continues to refer to its modern V8 engine family as Gen III and Gen IV, but to enthusiasts who quickly became fans of these engines, every engine on the planform’s nicknamed “LS.”

5 Reasons LS Engines Are So Popular?

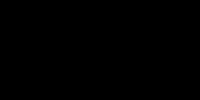

At a high level, these engines are extremely reliable, generate a lot of power, are lightweight, and are cheap. This is the real takeaway, but a more detailed analysis is as follows:

1. Engine Strength

Snap-fit-cross-bolting is the engine’s secret ingredient. General Motors designed the Gen III LS with a Y block design, which previous small blocks didn’t have.

The reason this is important is that it allows for the use of 6 bolt main caps on the crankshaft. Four bolts are facing vertically, and two bolts are horizontally that clamp the block wall to the main cap.

This provides outstanding block rigidity and a great crankshaft. Furthermore, this design allows for extra-long head bolts that thread far into the block. The result is less cylinder bore and distortion and variation which means more strength.

2. Cost-Effectiveness

These engines are from 1997. As everyone knows, a huge amount of supply + moderate demand = less cost. And, there has been an increase in engine swapping (it’s not uncommon to see a Mazda Miata sporting an LS1). LS engines are in high demand in junkyards nationwide. This artificially lowers the price of a new one. Unlike a company like Apple, which controls the production of its technology products, a lot of manufacturers build parts for Chevy which creates more competition and ultimately reduced prices.

Chevrolet has produced the LS engine since 1997, and they came in everything with rear-wheel drive. Since they were put in so many cars, they’re in abundance. This has kept prices fairly low, and with the rising popularity of LS swaps the prices have dropped further. You can walk into any junkyard and find an LS engine within a few minutes.

Replacement parts are also very cheap, and this is due for a number of reasons. The main reason is that Chevrolet is one of the largest manufacturers in the US, and many companies make parts for Chevy products. Some parts are expensive, but they’re cheap compared to Japanese high-performance engines.

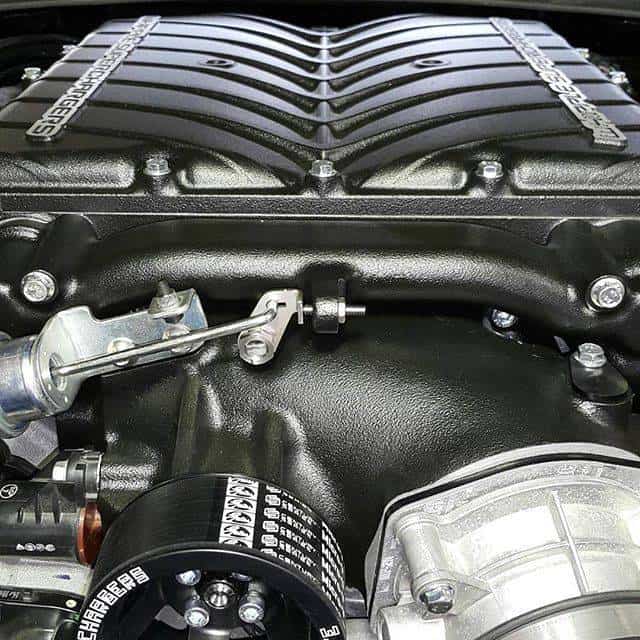

3. Aftermarket Updates

As previously mentioned, because the price is so low on these engines, aftermarket upgrades for LS engines have literally taken off to unprecedented heights. Intake/exhaust upgrades are merely bolt-on accessories. A few common modifications are a bolt-on supercharger or a less costly high-performance camshaft.

There are a plethora of aftermarket engine swap kits. Experienced professionals to make putting an LS engine into just about any car pretty straightforward. Simply put, the aftermarket allows for cost-effective performance upgrades. Previously, only race cars had these upgrades.

4. Performance/Displacement

GM’s objective for the LS engine was to create a solid amount of horsepower and torque. As previously mentioned, the factory heads flow nearly as well as a race car. Modern technology allowed innovation in the areas of port lengths designed to find the ideal head designed.

Port shape, size, and length affect torque and horsepower ratings, surprising many enthusiasts.

A few other noteworthy items involve the intake manifolds and cam size. Modern technology was used to produce usable power at low RPMs and solid power up high.

Similarly, technological advances led to them making the cam core massive which means you can easily fit a .600+ lift cam and it won’t harm the motor. Heck, even an intake/exhaust modification can result in a performance increase of roughly 100HP. LS engines respond favorably to even the most basic modifications.

5. Combination of Size and Weight

LS engines are typically smaller and lighter than the competition. This is important and has led to their popularity because they are so much easier to swap into cars with small engine bays. The “retro” pushrod design, combined with modern technology in the engine block, is key for the compact engine size. Nearly all modern engines have overhead cams which certainly allow for better performance in the long run but result in a significantly heavier and larger engine.

How Does One Choose?

Everyone would like to purchase the supercharged LS9 and install it. But, the trust of the matter is that’s not always the best option. And, there are a lot of options when trying to determine which LS engine to choose.

I chose the LS7 as I think it’s one of the best engines they have ever produced. And, it produces a tremendous amount of horsepower and it’s naturally aspirated. However, I bought my restomod used which means the original owner bore the true cost of the engine. So if I had to choose one engine here is what I’d do.

That said, many people choose the LS3, and it’s one I find myself recommending to a lot of people. As we covered earlier, the LS3 was introduced to the world in 2008. Since it has become the most popular base model engine ever introduced in a corvette. The LS3 uses Gen IV design and what makes it particularly attractive is the cylinder heads. LS engines have smooth-flowing heads. The LS3 elevates it. Hot Rod Magazine calls the 293 cfm intake one of the best in any car.

Are There Any Cons with the LS Engines?

Admittedly, I think the LS engines are some of the best on the planet for restomodding Chevrolet cars, especially a Camaro like the one I own. I researched motors to restomod into my Camaro and here are the cons I found with the LS engines (full disclaimer, I have not experienced any of them personally):

Oiling Systems

- Piston Ring Seals. It’s been widely reported that LS variants have been plagued with bad piston ring seals. This issue can cause oil consumption issues. As this issue gets worse it can also create an increasing amount of blow-by in the engine.

- Oil Pump Captivation. The stock oil pump reportedly starts to cavitate above 6,000 RPM. Due to the limited rev capabilities of the LS engine, this is not as much of a problem in the production version of the engine. However, in performance applications where engines are expected to routinely rev past 6,000 rpm, it creates oil pressure problems as the oil pump starts cavitating.

- Non-Priority Main Oiling. A common upgrade on aftermarket blocks is priority oiling. Priority main oiling ensures that oil goes to the mains first and to the heads as a secondary path. This ensures that oil pressure drops have a minimized effect. A stock LS block does not feature priority main oiling. In an OEM setting priority, the main oiling doesn’t really make sense. Reason: engines spend little time at high rpm.

Engineering

- Skirted Block. While the skirted block design strengthens the block it does limit the ability to reduce windage through traditional methods. The use of crank scrapers and power pouches is completely removed and the effectiveness of windage trays is reduced.

Drivetrain

- While the pushrod design is great for the packaging and is one of the primary reasons it is so popular in engine swaps. The valve train in a pushrod engine is a limiting factor. The complexity of the valve train creates limitations on the RPM range possible.

- A pushrod motor also requires more valve train parts when compared to an OHC engine. This creates more opportunities for parts to fail along with increasing the friction created in the valve train as there are more moving parts.

- Another basic issue with the LS and all pushrod motors it the limitations of the actual valves that can be used. The pushrod engine is limited to one intake and one exhaust valve which can limit the volumetric efficiency. The OHC engine has featured up to 5 valves per cylinder to increase it’s performance capabilities.

Maintenance

- The packaging of the pushrod design of the camshaft is located in a difficult to get to location. When replacing the camshaft in an LS you will commonly need to either remove the engine or the radiator to be able to access it.

Related Questions:

The LS engine family is known for having smaller proportions than its competitor’s engines, making it much easier to swap into cars with small engine bays. They are also very powerful and relatively cheap.

The LS on a Chevy engine means Luxury Sport. LS was Luxury Sport and LT was Luxury Touring. LS used to be the high-end (save SS) model back in the ’80s with the CL (Custom Luxury) package.

The Best LS Engines are the LS9/LSA: Made for the 2009-2013 Corvette ZR1, the LS9 is a supercharged 6.2L engine rated at 638 horsepower — the most powerful of all small blocks. LS1: This is the one that started it all and is great for smaller vehicles. The LS7 was introduced in 2005, and the LS7 sported 427 cubic inches, making it the largest small block ever.