Classic Car Tire History

The majority of cars built during the late Forties, Fifties, and the early Sixties came equipped with bias-belted, or bias ply, tires. And, Eventually, cars evolved to become significantly bigger and heavier. At the same time, gas became more expensive, and automobile and tire manufacturers began developing new technologies that could handle the additional weight, provide improved performance, and maximize gas mileage. Without further adieu, please enjoy Ultimate Restomod Tire Buyers Guide.

So, as we think about restomods, especially someone making the decision to restomod or just restore a classic car, let’s talk about classic tire history. This will be important when plotting a course forward for the car owner.

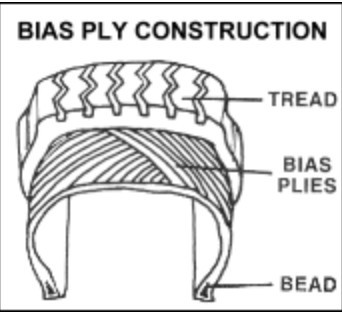

Bias-ply and bias-belted construction

The construction of a tire goes much deeper than what you see on the outside surface. However, the body of a tire is referred to as a “casing” and is composed of multiple layers, which are called plies or belts.

Belts under the tread give the tire strength, prevent the rubber tread from undulating, and provide resistance to puncture. In addition, the materials used for bias-ply tire construction over the years have included rayon and nylon, with rayon more commonly provided as original equipment and nylon being offered as an extra-cost option. And, in the late sixties, fiberglass belted tires were a popular option on many performance cars, as the fiberglass made the tire stronger and improved its useful life of the tire.

As the tire casing is being constructed, the various layers (plies) are laid on top of each other in pairs. The innermost plies are normally placed at a 45-degree angle, or bias, which means the plies are placed diagonally to each other, forming an “X” as they run from one bead of the tire to the other (inside edge to outside edge).

The outermost plies run lengthwise around the circumference of the tire. The purpose of this is to provide additional strength to the tire. Most tires made for passenger cars during the late 1940s-early 1960s were built with 4-ply construction, which meant they had 2 layers, or 2 pairs of plies, which made them 4-ply tires.

Tire strength

This type of tire construction makes the sidewall area of the casing very strong, which allows the tire to support more weight. In addition, this was very important at the time as cars were beginning to offer additional equipment such as power steering, air conditioning, and lots of other accessories that greatly increased their overall weight.

The tread area of bias-ply tires is very firm, and this design ensures good contact of the tread with the road. In fact, the design of this type of tire can cause a very firm, even harsh ride. However, this is one of the reasons many cars during this era were so softly sprung, in an attempt to provide a comfortable ride for passengers.

In addition to the ride characteristics, this type of construction doesn’t flex very much, which creates rolling resistance and additional heat as the tread area of the tire contacts the road. Furthermore, this heat can build up to a point where it actually causes the tire to wear faster than normal and is compounded by an underinflated condition, as well as poor vehicle alignment.

Flat spots

Bias-ply tires are also prone to developing flat spots, especially if the vehicle sits for extended periods of time. And, sometimes these flat spots are permanent and cause poor ride and handling. However, it is possible for the tire casing to return to its normal shape as heat builds up when the vehicle is driven.

Vehicle tires and wheels at this time were narrow compared to today’s standards, which creates confusion when attempting to install new tires on a vintage car today. In addition, today’s tires have a lower profile, with a wider tread area which can cause appearance problems involving ride height with older cars.

It is also important to make sure proper clearances are maintained for steering, as some of the built-in factory tolerance computations were quite close. For additional information on specific tire sizes for your classic car, please refer to our Tire Size Conversion Guide (planned future site addition).

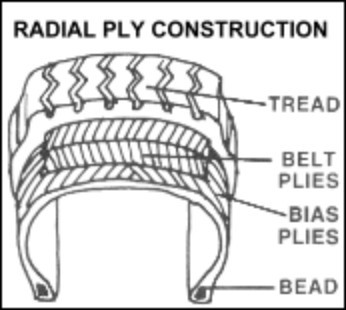

Radial ply construction

Radial-ply tires are constructed in many ways much the same as bias-ply tires, with a couple of notable exceptions. In addition, the innermost plies on a radial tire are not angled as much as on bias-ply tires. Moreover, radial plies normally have only a 2-degree or less angle to the plies, which makes them concurrent with one another, running sideways across the tire from bead to bead.

The belts in a radial-ply tire are normally steel. Radial ply tires are more flexible than bias-ply tires, which allows the tread and sidewall of the tire to conform to the contour of the road better, especially during cornering. In addition, the result is reduced rolling resistance, improved handling and traction under all conditions, and a reduction in heat build-up, when properly inflated.

The reduced rolling resistance of radial-ply tires also allows for a notable increase in gas mileage, often well over 10%. In addition, radial ply tires are less likely to fail due to blowout and are more resistant to puncture when kept inflated at proper pressures. So, the greater flexibility also allows for a lower aspect ratio, which is covered below.

Numeric sizing

American tire manufacturers used to use numerals to denote the various tire sizes. A few examples are:

6.00×12, 7.50×14, and 7.10×15

The first three numbers indicate the size of the tire, by measuring the casing at its widest point. Also referred to as section width, the first size listed above (in bold), as an example would be 6 inches wide. (6.00 = 6 inches)

The last numbers indicate the diameter in inches of the wheel that the tire is designed to be mounted on. Using the same example above, the wheel would be 12 inches in diameter. So, the tire has a section width of 6 inches by a diameter of 12 inches or 6.00×12

Alpha-numeric sizing

With cars becoming heavier and more demands being placed on them by drivers, the numeric sizing no longer provided enough information to ensure the tire would perform properly under harsher conditions. And, since weight plays such a critical role in tire safety, new alpha-numeric sizing was introduced to provide this information in the form of a load range rating.

A few examples: A78x14, G78x14, and L78x15Using the example in bold above, the letter at the beginning denotes the load range rating or load carrying capacity of a tire. Moreover, this designation was created by the Department of Transportation (D.O.T.) by using letters of the alphabet to indicate the load range of a tire.

The letters “A” through “L” are used, skipping the letter “I” since it could possibly be confused for the numeral “1” (one). While the load-carrying capacity of a tire is a mathematical formula that considers the physical size of the air chamber as well as how much air pressure is in that chamber. So, to increase the load-carrying capacity of a tire, you have to either increase the air pressure of the tire or increase the size of the air chamber in the tire by going to a larger-sized tire.

The letters of the alphabet relate to the load range/air chamber size with “A” being the smallest, “B” the next larger, etc. For example, A78x14 would be a smaller load range than B78x13With this change, the D.O.T. started including the Aspect Ratio as well, which is why the numbers immediately after the load range letter are different.

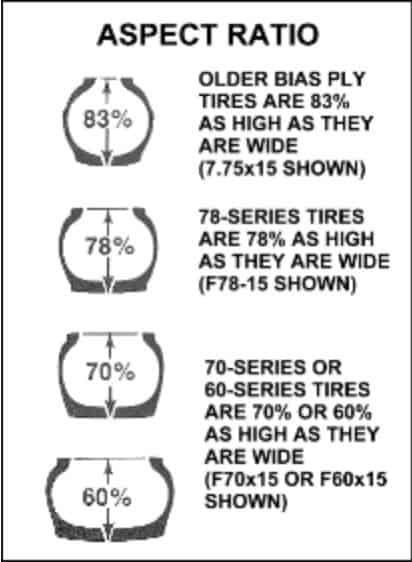

Aspect ratio

The Aspect Ratio of a tire is the relationship of its height to its width when mounted and properly inflated on a wheel rim of the correct size for the tire. Furthermore, this is expressed as a percentage of the section height to section width in a two-digit number. For example:

80, 70, 60

Also referred to as the tire’s series, the combination of a tire’s section height and section width is expressed as a percentage, or .70, for example. So, a tire with this configuration would be a 70 Series tire. To determine this you would use this formula:

Tire Section Height vs. Tire Section Width = % of Tire Section Width at the widest point of the casing is the Series number of the tire.

For example, if you had a tire size of G78x15, the sidewall height would be 78% of its section width. The relationship of the section height to section width determines the shape of the tire on the rim, and therefore, its characteristics under various load conditions. As a result, this is why radial tires appear to be underinflated at times, even though the pressure in the air chamber is correct. on the other hand, a sidewall height with a smaller percentage to width ratio would exhibit more sidewall stiffness, a harsher ride, a wider tread area on the road, and a quicker response to driver input.

Raising the Aspect Ratio allows the tire more deflection under load and a softer ride, while at the same time providing a smaller tread contact with the road and slower response times. Confused? A 50 Series tire would have approximately 50% as much sidewall height as it would overall width, which would give it a harsher ride and quicker response than a 60 Series or a 70 Series tire would.

Euro-metric sizing

At about the same time domestic tire manufacturers and the D.O.T. were changing from Numeric Sizing to Alpha-Numeric Sizing, the European tire manufacturers also changed to Metric Sizing, which we refer to as Euro-Metric to prevent confusion. Without a doubt, this change occurred due to the change from bias-ply tire construction to radial-ply tire construction in Europe.

Examples of Euro-Metric Sizing would be: 185R13, 175R15, and 215R15Using the example in bold above, the first three numbers express the tire’s section width in millimeters, just the same as the old Numeric Sizing expressed this measurement in inches. The “R” indicates the tire is of radial ply construction, and the last two digits express the wheel diameter the tire is designed to fit. However, it’s important to note that some Euro-Metric tires have Aspect Ratios listed in the sizing, while others don’t.

This is due to the fact that the Euro-Metric system was originally set up with an Aspect Ratio of “82” and it wasn’t included in the sizing at that time since all tires had this as the default. Over the years, technology allowed improvements in tire performance by increasing the section width of the tire and reducing the height of the sidewall of the tire.

Since there could now be variations in the Aspect Ratio, this number would need to be included when stating the size of the tire. For example, an example of a Euro-Metric tire size would be:215/75R15This example shows a section width of 215 millimeters, an Aspect Ratio of 75, radial ply construction, and a wheel diameter of 15 inches.

P-metric sizing

This is an easy one. P-Metric Sizing is virtually the same as Euro-Metric Tire Sizing, except the D.O.T. added the “P” to indicate that the tire was designed for passenger car use for load-carrying capacity limits.

During the late 1970s and early 1980s, America was hit by a fuel crisis that changed the way Americans looked at their large cars. At the same time, Europeans had been dealing with high fuel prices for some time and had developed smaller, more fuel-efficient cars to maximize fuel economy. Moreover, radial tires with their lower rolling resistance were a big part of the overall fuel economy.

P-Metric Sizing provided more information than previously available, showing not only that the tire was designed for passenger car use, it also indicated the section width, Aspect Ratio, type of construction, and wheel diameter size.

Using the same example above in Euro-Metric Sizing, this is how it would look in P-Metric Sizing:

P215/75R15 The “P” denotes passenger car load carrying capacity, the “215” reflects the section width in millimeters, the “75” is the Series, “R” is radial construction, and “15” is the wheel diameter size.

P-metric sizing for high-performance tires

Performance versions of P-Metric Sized tires will often add two or three additional numbers followed by a letter to the end of the sizing. This indicates the Service Description of the tire. To get this code, two things are considered: the Load Index and the Speed Rating of the tire.

The Load Index is a number between 0 and 279, and covers all load capacities for all tires. From the smallest motorcycle tire to the largest heavy-duty equipment tires, they all receive ratings within this numerical range. Passenger car tires normally have load indexes rated from 75 to 100. We have provided a Load Index Chart below listing load indexes from 74-150.

The Speed Rating is a letter (or symbol) that designates the rating the tire received an indoor wheel testing, normally using the European ECE 30 Indoor Wheel Testing model as the standard.

Load Index Chart

| Load Index | Load (lbs.) | Load Index | Load (lbs.) | Load Index | Load (lbs.) |

| 74 | 827 | 100 | 1764 | 126 | 3748 |

| 75 | 853 | 101 | 1819 | 127 | 3858 |

| 76 | 882 | 102 | 1874 | 128 | 3968 |

| 77 | 908 | 103 | 1929 | 129 | 4079 |

| 78 | 937 | 104 | 1984 | 130 | 4189 |

| 79 | 963 | 105 | 2039 | 131 | 4299 |

| 80 | 992 | 106 | 2094 | 132 | 4409 |

| 81 | 1019 | 107 | 2149 | 133 | 4541 |

| 82 | 1047 | 108 | 2205 | 134 | 4674 |

| 83 | 1074 | 109 | 2271 | 135 | 4806 |

| 84 | 1102 | 110 | 2337 | 136 | 4938 |

| 85 | 1135 | 111 | 2403 | 137 | 5071 |

| 86 | 1168 | 112 | 2469 | 138 | 5203 |

| 87 | 1201 | 113 | 2535 | 139 | 5357 |

| 88 | 1235 | 114 | 2601 | 140 | 5512 |

| 89 | 1279 | 115 | 2679 | 141 | 5677 |

| 90 | 1323 | 116 | 2756 | 142 | 5842 |

| 91 | 1356 | 117 | 2833 | 143 | 6008 |

| 92 | 1389 | 118 | 2910 | 144 | 6173 |

| 93 | 1433 | 119 | 2998 | 145 | 6393 |

| 94 | 1477 | 120 | 3086 | 146 | 6614 |

| 95 | 1521 | 121 | 3197 | 147 | 6779 |

| 96 | 1565 | 122 | 3307 | 148 | 6944 |

| 97 | 1609 | 123 | 3417 | 149 | 7165 |

| 98 | 1653 | 124 | 3527 | 150 | 7385 |

| 99 | 1709 | 125 | 3638 | 1lb. = .4536kg |

Speed Rating Chart

| SPEED SYMBOL | SPEED MPH | SPEED KPH |

| M | 81 | 130 |

| N | 87 | 140 |

| P | 93 | 150 |

| Q | 99 | 160 |

| R | 106 | 170 |

| S | 112 | 180 |

| T | 118 | 190 |

| U | 124 | 200 |

| H | 130 | 210 |

| V/VR* | 149 | 240 |

| W/ZR** | 168 | 270 |

| Y/ZR** | 186 | 300 |

*Tire Speed Symbols currently in use include the Service Description to identify the speed capability of the tire; for example, P215/65R15 95V would indicate a maximum speed of 149 mph. Previous ratings included the speed symbol in the size designation only; for instance, P215/65VR15, and the maximum speed was listed as “above 130 mph” (210 kph).

**All tires with a Speed Symbol of V, W, or Y (above 149 mph/240 kph), may include, at the discretion of the tire manufacturer, a Service Description of “ZR” in the size designation; an example would be P275/40ZR17. If a Service Description is not included with the size designation, the tire manufacturer must be consulted for the maximum speed capability of the tire; so P275/40ZR17 would indicate that the Speed Rating is over 149mph.

If a Service Description is included with the size designation, the speed capability is limited by the speed symbol in the Service Description; for example, P275/40ZR17 93W indicates a maximum speed of 168 mph/270kph.

Ultimate Restomod Tire Buyers Guide – A Beginner’s Guide To Buying Whitewall Tires

Whitewall tires, also known as white sidewall tires, are really popular with classic car enthusiasts. In the old days, whitewall tires were a premium upgrade, as they made your car look a bit flashier.

In the six decades since whitewall tires became a hit, their popularity has dwindled some. However, they’re still considered a premium upgrade for classic cars, even today. That’s why there are a few companies that offer whitewalls in various sizes for classic cars. If a brand new set of whitewalls is in your budget, this guide is for you.

Where to Buy Whitewall Tires

A few tire manufacturers produce whitewall tires, the major ones being:

- Coker Tire

- BF Goodrich

- Goodyear

- American Classic

- Firestone

Whitewall Tire Options

There are two different types of whitewalls. Let’s explore each option to figure out which one fits your needs the most.

Bias-ply Whitewalls

You can buy bias-ply whitewalls, which a lot of classic car enthusiasts will do if they’re interested in being as authentic as possible. Bias-ply tires aren’t really used for new vehicles anymore (outside of extreme off-roading), because bias-ply tires don’t last very long and are prone to blowouts when used on the street. However, if you need to have a car that’s original as possible, this is the way to go.

Whitewall Radials

Whitewall radials are a better choice for classic car owners who want to drive their cars regularly. They last longer, are less likely to blow-out and have better traction.

Tips For Buying and Mounting Whitewall Tires

Buying whitewall tires isn’t like buying regular tires. There are some things you have to keep in mind to ensure that you get the best driving and showing experience possible with your whitewall tires. We have a few important tips for you:

- When you pay someone to mount the tires, make sure they have experience with whitewalls. An inexperienced technician can accidentally scuff up the whitewalls and ruin them.

- If you decide to buy a set of bias-ply whitewalls, make sure the technician mounting the tires knows how to handle bias-ply tires. If the tires are installed incorrectly, the tubes can get punctured.

- Decide which tread pattern you want first before shopping for whitewalls. There are a lot of tread pattern options available. Some patterns are meant to look like they’re original, older tires. This is great if you’re shooting for authenticity but bad if you’re shooting for traction and performance.

Ultimate Restomod Tire Buyers Guide – Restomod Tire Buying Guide

Buying new tires can be a confusing chore. What do all those numbers mean? And, of course, how do I know when I need new ones? Taking care of your tires and maintaining good driving habits can help extend the life of your tires, but eventually, you’ll need a new set.

That’s why I’ve put together this comprehensive tire buying guide with all the information you’ll need to help make an informed choice. The first order of business: know when your tires need to be replaced.

Do you need to buy new tires?

Tire manufacturers typically recommend that your tires be changed every six years, regardless of wear and tear. Check your owner’s manual to see what your tire maker suggests. In the case of a restomod owner, particularly those living in states with a winter season, I recommend getting new tires every six years.

Have a mechanic inspect your tires regularly for signs of wear or damage. You should also check them out regularly, as well. Look for the factors below:

- Tread depth – Place a penny upside down into the treads or grooves. If you can clearly see Lincoln’s entire head, your treads are likely worn and it may be time to replace them.

- Sidewall cracks – Check for cuts or deformations in the sidewalls. If you see any grooves, your tire could be on the verge of a leak.

- Bulges or blisters – A noticeable bulge or blister could indicate a weak outer surface.

- Vibration – Does your car vibrate noticeably when you’re driving? This could indicate problems now and potential danger down the road.

If you need new tires, buy the size and type specifically for your car. Mixing different tire types could not only cause damage but could also be dangerous.

Buying the Right Tires

Tire terminology you should know

On the sidewall (the outer and inner sides) of a tire, you’ll find the following information:

- Tire Specs – Size, construction, and speed rating. The speed rating is the approximate speed a tire can safely maintain over time. The higher the rating (A is the lowest and Y is the highest), the better the handling and control. However, a higher speed rating may result in shorter tread life. Check with a professional for the proper speed-rated tire for your model.

- Department of Transportation Safety Code – This code certifies the tire manufacturer meets the U.S. Department of Transportation tire safety standards. It is followed by your tire’s ID number, plus information about where and when the tire was manufactured.

- Uniform Tire Quality Grading (UTQG) – The testing method used to grade a tire’s treadwear, traction, and temperature. Read a Consumers report article, here.

- Icons – Features a tire’s unique benefits. For example, “M+S” means the tire meets the Rubber Manufacturers Association standards for mud and snow.

How to read a tire’s sidewall

The diagram below shows where you’ll find this information on a tire.

Note the code on the sample tire above is P195/60R16 85H. The table below shows what each abbreviation in the code means.

| P | Service Description P = “passenger car”LT= “light truck”ST = “special trailer”T = “temporary” |

| 195 | Tire Width Tire’s section width – distance from sidewall edge to sidewall edge. The higher the number, the wider the tire. |

| 60 | Aspect Ratio Tire’s section height compared to its section width. Lower numbers mean a short sidewall with improved steering & handling. |

| R | Internal Construction R = radial construction |

| 16 | Rim Diameter Wheel diameter, in inches, for which the tire was sized. |

| 85 | Load Index Measurement of how much weight each tire is designed to support. The larger the number, the higher the load capacity. |

| H | Speed Rating Speed the tire is designed to run for long periods.S = 112 mphT = 118 mphU = 124 mphH = 130 mphV = 149 mphZ = Over 149 mphW = 168 mphY = 186 mph(Y) = Over 186 mph |

Another factor to consider in buying tires is the tread-life warranty– an estimate based on the type of tire and the number of miles it can be expected to travel under normal driving conditions.

Ultimate Restomod Tire Buyers Guide – Understanding Tire Warranties

Tire Life

Most tire makers have determined that the usable life of a tire is either six years from the date of purchase or when there are just 2/32nds of an inch of tread left. While there’s no federal law regulating tire wear, Ron Margadonna, senior technical marketing manager for Michelin tires, says that the 2/32nds measurement has been adopted by most states.

This measurement is difficult to visualize without a reference point, but there are at least two indicators that a tire is nearing the end of its life. Tires sold in North America are required to have tread-wear indicators, which are found in the tire tread’s grooves. The wear indicators look like small bars of tread that run perpendicular to the groove. If the wear of the tire has reached these indicators, it’s time for a new tire.

Another measure is the penny method. Put a penny in the groove of the tire, upside down and with Lincoln’s head facing you. The distance from the top of Lincoln’s head to the edge of the coin is about 2/32nds of an inch. So if the top of Lincoln’s head is showing, you’ll need to replace the tire. A similar method involves using Washington’s head on a quarter to measure 4/32nds of an inch, but this is a safety indicator, not a way to support a claim that a tire has worn out prematurely.

Tread-Life Warranties

Every tire manufacturer offers tread-life warranties. Nearly every tire has a mileage estimate (the exceptions being some high-performance tires, track/competition tires, and most winter tires). The tread-life estimate is based on the type of tire and the number of miles that can be expected under normal driving conditions, Margadonna says. For example, high-performance tires found on a sports car are softer and have a lower mileage estimate than the harder tires typically found on economy cars.

If a tire has worn out evenly across the tread well before its estimated mileage limit, it may qualify for replacement under the tread-life warranty. You must show proof of purchase and proof that the tires were rotated properly at the recommended intervals. In this situation, the manufacturer prorates the cost of the new tire based on the percentage of remaining tread on the old tire and the price of the replacement tire.

Prorating

Maradona says this prorating method is similar to how companies reimburse owners under-car battery warranties. He uses the example of a tire with an 80,000-mile warranty and a person who was only able to get 70,000 miles of life out of it. “You haven’t reached the mileage threshold that we think you should have reached, so we owe you 10,000 miles,” he says.

Some notable exceptions to tread-life warranties are winter tires and split-size fitments. Michelin is one of the only manufacturers to have a tread-life warranty on winter tires. Owners must remove the tires during the off-season to ensure proper usage and keep the warranty in good standing. “We want them to be on in the fall, around October 1, and off in the spring, around April 1,” says Margadonna. “If not, we reserve the right to void that warranty claim.”

Some sports cars have different-size tires that cannot be rotated using the traditional method. In split-size fitments like this, rear tires get half the mileage warranty of the front tires. That’s because the rear tires wear out almost twice as fast as the fronts, Margadonna says.

Road Hazard Warranties

Tire stores typically offer these warranties, which come into play if you get a flat tire. If the tire can be repaired, the repair is covered for the duration of the warranty. If the tire can’t be repaired, the company will prorate the remaining mileage toward the purchase of a new tire. Some companies even throw in free tire rotations for the duration of the warranty.

Road hazard warranty prices vary, based on the tire and the vendor, but on average, they range from $10-$20 per tire. Edmunds editors have mixed feelings about them. Some have put them to use, while others feel that they are a waste of money.

Profit Driven

The warranties are a major source of profit for tire shops, but that doesn’t necessarily mean they don’t have value for drivers. These warranties are essentially insurance policies. If you’re considering whether to buy a road hazard warranty, think about how many times you’ve had a nail or a puncture in your tire in the last few years.

Was the amount you spent on repair or replacement enough to justify the warranty? Do you drive in an area where there is a lot of debris on the road? Or are you just the kind of person who feels better when you buy the extended warranty on a product? If your answer to any of those questions is a yes, these warranties might be worth your money.

Workmanship and Materials Warranty

The workmanship and materials warranty protects the consumer from any defects in the manufacturing or materials used in the tire. Most manufacturers offer this coverage for the life of the tire.

“Workmanship and materials mean that we stand behind the product, should you run into some issue,” says Maradona. Some of the problems that would be covered include severe cracking in the sidewall or the loss of a block of the tread. “If there was something wrong with the tire that we were at fault for, as a manufacturer, we stand behind our product,” says Maradona.

If a workmanship or manufacturing failure comes up within the first 2/32nds of an inch of tread, most manufacturers will replace the tire free of charge. Anything after that will usually be prorated.

Manufacturer Special Warranty

A manufacturer’s special warranty typically takes the form of a 30-day promotional trial. This is the best time to determine whether the tires you just bought are right for you. Consumers are eligible for a full refund or credit toward the purchase of another tire if they are not satisfied with their tires for any reason. Bridgestone, General Tire, Michelin, and Yokohama are just a few of the manufacturers that offer these trial programs.

In March 2011, Michelin launched its “Michelin Promise Plan,” which Margadonna says is unique in the industry. This warranty program has three components: a 30-day satisfaction guarantee, a limited mileage warranty, and flat-tire changing assistance.

The flat-tire changing assistance makes the program stand out from its competitors. If a customer experiences a flat tire and does not know how to change it, or just does not want to do it himself, he can call a toll-free number and roadside assistance will install the spare free of charge. If the customer has no spare, Michelin will arrange for a tow to the nearest Michelin-approved repair center for up to 150 miles.

Uniformity Warranty

The uniformity warranty is one that a driver might never encounter. This warranty covers excessive vibration or ride disturbances caused by a tire. For most companies, the buyer has to notify the company within the first 2/32nds of an inch of tire tread.

A problem like that would be “instantaneous” and very obvious to a driver, Margadonna says. “So we tend not to cover ride issues well into the life of the tire.”

In most circumstances, a uniformity problem would be covered under the 30-day manufacturer’s special warranty, but the uniformity clause is there to protect the consumer against problems that happen past that.

What Voids Your Warranty?

Just as you can void your car’s warranty, you can void your tire’s warranty, too. The big one to watch out for is improper maintenance. If the tire manufacturer does not see proof that the tires were inflated, rotated, and aligned properly, chances are your warranty claim will be denied. Other warranty killers include vandalism, racing, off-roading, and damage from snow chains.

Inflate, Rotate, and Evaluate

With any warranty, the manufacturer expects you to do your part to maintain the product to its standards. The Bridgestone tire manual, for example, tells consumers to do these three things to ensure long tire life:

- Keep your tires inflated to the recommended tire pressure to ensure even wear.

- Rotate the tires based on the manufacturer’s recommendation or every 5,000 miles, keeping a record of the service.

- Inspect your tires periodically, looking for any bumps or inconsistent wear patterns.

Don’t Cut Corners on Safety

These warranties may seem like too much to keep track of, but if you take a few basic precautions, you’ll not only reduce the chances of a tire wearing out prematurely but also be fully prepared for a claim. Hang onto your purchase receipt and keep a record of all tire rotations and alignments. Keep in mind that it is better to miss out on a warranty claim than to run the tire to the end of its tread life and compromise your safety.

Ultimate Restomod Tire Buyers Guide – Related Tire Pressure Questions

Find your optimal operating tire inflation pressure in the owner’s manual and on a sticker located on the inside of the driver’s door.

Find your optimal operating tire inflation pressure in the owner’s manual and on a sticker located on the inside of the driver’s door.

Performance is best when all 4 tires are the same size, tread pattern, and age. Tires that vary in those factors can cause handling and stability problems. However, some cars have different size tires in the front and rear, so check your owner’s manual.

Generally, not recommended. It could affect handling and maximum speed limit.

This is not typically recommended. You may be unaware of past hazards or mistreatment the tires underwent.

In addition to driving responsibly, there are other ways you can prolong tire life: Check tire pressure regularly, rotate tires regularly as outlined in your owner’s manual to help equalize tread wear, check wheel alignment as recommended by your carmaker

Taking curves and corners fast abrupt accelerating and hard braking are a few driving habits that negatively impact a tire’s life. This can cause excessive heat that wears the tire out more quickly be sure to avoid hitting curbs, potholes, and things of that nature.